- 首页

- About Us

- Product Center

- Technical Support

- Contact Us

- English

-

全国服务热线:

18684678662(周经理)

18670066189(莫经理)

purpose:As a degradation agent in polypropylene processing。

usage method:After mixing with polypropylene base material in a certain proportion, it is hot extruded and granulated with polypropylene.

remarks:Large continuous granulation equipment can be added through the granulator additive adding system. Adjust the proportion with powder feeding according to the target melt index required by the product. Small equipment can directly use base powder and polymer material zy-101 degradant to premix in a certain proportion according to the required melt index, and then co extrude and granulate.

Product shelf life:Below 30 ℃: 1 year

matters needing attention:This product will have a certain degree of hedging effect with antioxidants (phosphite lipids, thioethers) in the granulation process, resulting in excessive dosage. Degradation efficiency decreases.

The storage time of this product should not be too long, and it should be used as soon as possible after the package is opened. When the package is intact, it is also recommended to use it as soon as possible to ensure the best degradation effect of the product. If this product is used after the shelf life, the degradation efficiency will decrease.

Recommended dosage:Taking the basic powder of polypropylene with melt index of 3g/10min (230 ℃, 2.16kg) as an example, the recommended dosage is as follows:

Target melt fingerg/10min (2.16 kg, 230 oC) | Reference dosage(ppm) |

10-20 | 1000-3000 |

20-30 | 2000-5000 |

30-40 | 4500-7500 |

40-60 | 6500-9000 |

≥60 | >8000 |

Note: the dosage of degradation agent is related to the processing temperature of the granulator, the additives used, the manufacture of the granulation mechanism, etc. the data are only for reference.

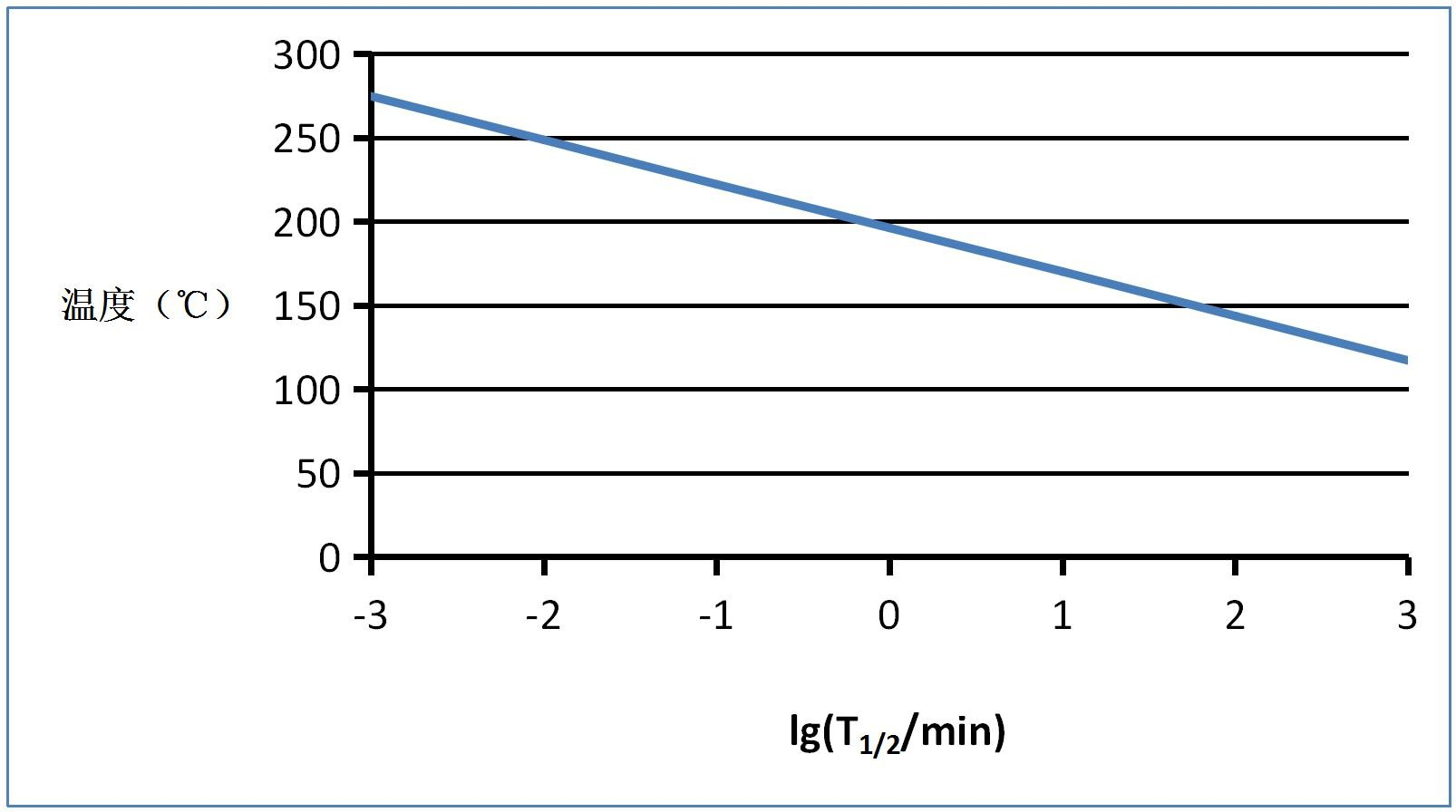

Attachment: polymer material ZY degradation agent half-life temperature curve